Explore the function, types, advantages, and limitations of rotameters in this comprehensive guide to this indispensable flow measurement tool.

Understanding Rotameters

Rotameters, widely recognized in the realm of flow measurement technology, are simple, precise, and versatile devices that can accurately measure the flow rate of liquids or gases. With their direct reading scale and relatively low cost, they have become indispensable tools in laboratories, industries, and other sectors requiring flow measurement.

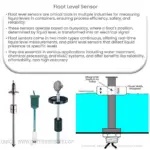

How Rotameters Work

At the core of a rotameter’s operation is a float that freely moves within a tapered tube. The concept of a rotameter can be traced back to the variable area flow meter, a principle first devised by Karl Kueppers in 1908. Its operation is predominantly based on the principles of buoyancy and balance.

- Buoyancy: As fluid enters the tapered tube, it creates an upward force that lifts the float. The buoyant force exerted is directly proportional to the flow rate of the fluid.

- Balance: The float reaches a state of equilibrium when the upward buoyant force equals the downward gravitational force acting on it. This balanced position is a direct indication of the fluid’s flow rate.

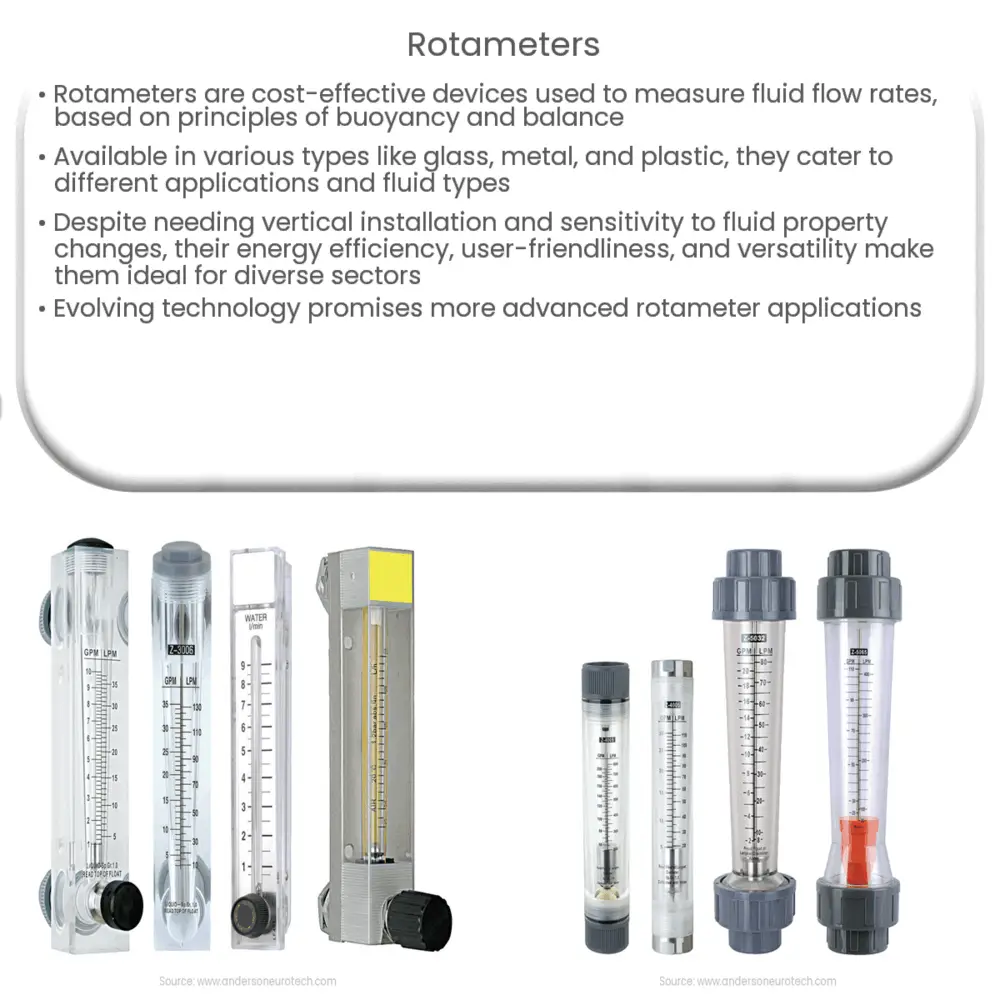

Types of Rotameters

Rotameters are available in various types, each designed to suit a particular set of applications. Their type is usually determined by the float and tube design, which could vary depending on the type of fluid being measured and the required measurement accuracy.

- Glass Tube Rotameters: These are the most common type of rotameters and are generally used for measuring the flow rate of non-corrosive liquids and gases. They offer a high level of visibility, which makes it easier to read the measurements.

- Metal Tube Rotameters: These are robust and ideal for handling corrosive or high-pressure fluids. The measurement scale is typically located outside the metal tube.

- Plastic Tube Rotameters: Suitable for handling corrosive fluids or gases, these rotameters are often used in chemical laboratories and industries. They offer the advantage of resistance against chemical attacks.

Applications of Rotameters

The wide application spectrum of rotameters can be attributed to their ease of use, reliability, and low maintenance. They are used in sectors ranging from chemical and petrochemical industries to water treatment plants. Particularly, they’re helpful in monitoring and controlling fluid flows, ensuring efficient operation of systems.

Advantages of Rotameters

Rotameters have several advantages that make them an attractive option for flow measurement. They require no power source, ensuring consistent operation even in areas with unstable or no power supply. With direct reading scales, they offer immediate visual indication of flow rate. Moreover, their simple design makes them easy to maintain and clean, minimizing downtime.

- Energy Efficiency: As rotameters operate without an external power source, they are energy efficient and reliable.

- Simplicity: With a design that’s easy to understand, install, and operate, rotameters are user-friendly.

- Versatility: Suitable for measuring flow rates of a wide range of fluids, rotameters are versatile tools for various industrial applications.

Limitations of Rotameters

While rotameters are highly advantageous, they are not without limitations. They rely on gravity for operation, which means they must be vertically installed with fluid flowing upwards. This may limit their applicability in certain settings. Moreover, changes in fluid properties such as viscosity and density can affect the accuracy of measurements.

- Orientation Limitations: The necessity for vertical installation can pose installation constraints in some situations.

- Sensitivity to Fluid Properties: Variations in fluid properties can impact the accuracy of readings, requiring regular calibration for accurate measurements.

Conclusion

In the realm of flow measurement, rotameters have stood the test of time, proving to be reliable, cost-effective, and versatile. With their capacity to measure a wide range of fluids and gases, they continue to serve a critical role in industries around the globe. Despite certain limitations, their benefits far outweigh their drawbacks, making them a key instrument in fields requiring accurate flow measurements. As technology continues to evolve, so does the functionality and application of rotameters, promising further advancements in flow measurement technology.