Contents

What Is a Wheel Offset?

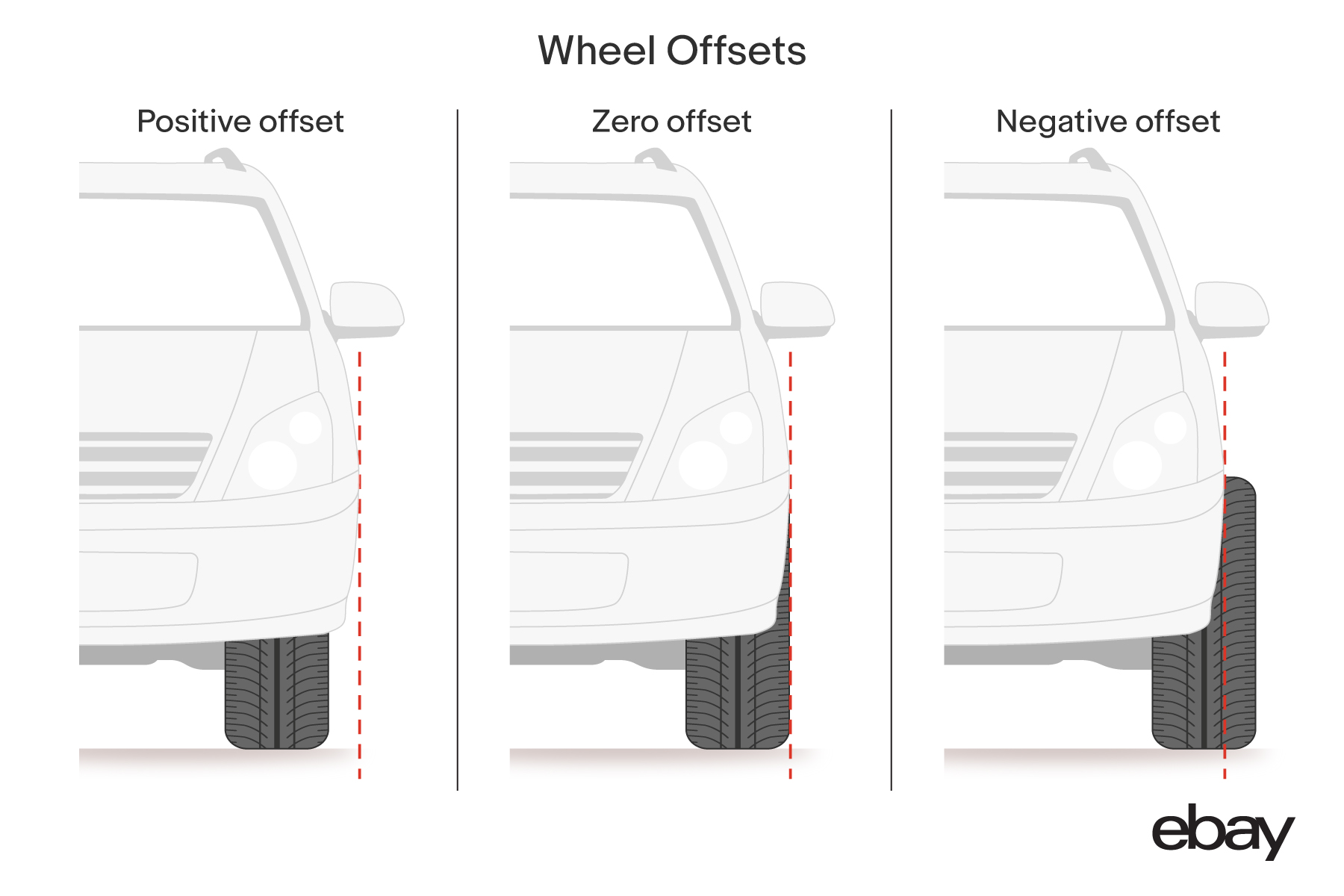

A “wheel offset” measures the distance from the wheel’s center line to the mounting surface. Wheel offset—either positive, negative, or zero—is commonly measured in millimeters.

- Positive offset: The mounting surface is toward the outer part of the wheel. This is the most common setup with factory wheels.

- Zero offset: This can also be referred to as no or center offset. The mounting point matches the wheel’s centerline.

- Negative offset: The mounting surface is toward the wheel’s inner part. This offset offers your vehicle an aggressive look and wider stance. It’s commonly used for off-road models.

In the world of wheels, the terms offset and backspacing are thrown around interchangeably. Yet, they aren’t the same. There are similarities, but it’s important to know the distinctions.

Backspacing is the distance between the inner flange of the wheel and the mounting plate. You need to know if your new wheels are wider than the originals. The offset should be changed to compensate for the additional width.

How to Measure Offset

You can measure the offset yourself if it’s not printed on the wheel. Even if it is printed, it can wear off or become hard to read.

Because the offset is the distance from the flange of the mounting hub to the wheel centerline, you can measure it at home. However, you can’t measure between beads while the tire is mounted, so you should use the sidewall. Here are some tips to get your measurements quickly.

- Remove the wheel and tire assembly from the vehicle.

- Lay it flat on the ground.

- Place a straight edge across your tire.

- Measure the space between the floor and the straight edge.

- Divide this measurement by two.

That measurement is the wheel centerline. The offset is positive if this number is less than the hub measurement. If it’s larger, you have a negative offset.

Shop now for wheelsHow Offset Affects Ride Quality

A change to the offset by even 5 mm is enough to alter how the vehicle handles. It’s going to affect the scrub radius to the same degree.

Jeep Wrangler OEM wheel offset vs aftermarket

If your factory wheels have a positive offset (which most do), you can install new wheels with a greater positive offset and use wheel spacers to adjust the contact patch back to the original position. This process ensures the scrub radius remains the same. However, you must ensure that the tires and wheels fit within the fender and don’t rub.

If your new wheels bring a negative offset, you can’t move the contact patch more toward the center. To determine how this offset affects the scrub radius, you have to put your vehicle on an alignment rack and get measurements.

When Wheel Offset Calculations Are Important

You only need to think about wheel offset when you order new wheels. If you aren’t replacing the wheels with OEM rims, looking at wheel offset calculations a good idea. Here are some concerns new wheels pose.

- Rubbing: You need a wheel with an appropriate offset, or there could be issues with the tires rubbing. The wheels and tires can start to rub the fenders and suspension parts, causing strange noises and premature failure.

- Poor Handling: With incorrect offset, the car isn’t going to handle the same. That’s why the wheels and tires were mounted the way they were. Changing offset can reduce grip, leading to poor handling in slippery situations and reduced brake performance.

- Wheel Damage: The tires and rims can be damaged if you don’t have the proper offset. Even though an aggressive stance looks cool, the wear it brings to the tires may not be worth it. The drivetrain also takes a beating whenever the wheels are under more stress.

When Do You Need a Tire Professional?

Unless you have a lot of experience working with wheels, it’s best to trust this process to a professional. Even qualified mechanics aren’t well-versed in this area. A technician can ensure everything will fit properly before you order new wheels.

An educated technician is going to verify the brake caliper clearance. With OEM wheels, the clearance can be as low as an eighth of an inch (4 mm). If the new setup brings that closer, there could be issues with your braking system. Installing a bare wheel and turning it to see the clearance is easy. If it becomes too tight, you’ll have to add wheel weights.

There’s also the issue of mounting the wheel. OEM and aftermarket wheels can be very different. It all rests on the drop center of the wheel. Typically, the drop center is on the outside of the wheel, so it gets placed with the outside up when using a tire changer. However, the narrow part of an aftermarket wheel may be on the inside instead. In this case, it must be placed on the tire changer. If it’s not done this way, the bead could stretch. You could damage the wheel, your changer, or yourself.

You may know how to put air in your tires, but do you understand how to torque the lug nuts properly? The nuts should always be torqued with a calibrated wrench to ensure they are secure. The brake rotors can wear unevenly and warp if the nuts aren’t tightened evenly.

Shop now for wheels