Abstract

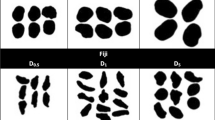

It is intuitional that most cactus spines are hard and sharp, but their structures and properties have never been systematically studied. Here, we report a comprehensive study on the microstructures and mechanical properties of spines from Echinocactus grusonii cactus for the first time by combining optic and scanning electron microscope investigations, x-ray microanalysis, as well as nanoindentation and tensile tests. It is found that the cactus spine consists of fibres with diameter of 5–15 μm and length of hundreds of micrometres and sclerified epidermis, but contains no mineralisation component as some hard substance does. The spine fibres have high crystallinity and in high alignment. Nanoindentation experiments show that the spine has much higher longitude hardness than that of bamboo reported in the literatures, although their transverse hardness is nearly identical to that of woods, crops, and bamboo. The indentation modulus of the spine cell wall is also within the same order of magnitude as woods, crops and bamboo, with detailed value similar to that of bamboo and slightly lower than that of woods and crops. The tensile strength of the dry spine is measured to be 140 MPa within the range of tensile strength of bamboo reported in the literatures. It is also found that the fresh spine has certain toughness, but the dry spine becomes brittle. The high crystallinity and high alignment of fibres in the cactus spines as well as the very small multifibrillar angle within each fibre can explain the special mechanical properties of the spines.

Similar content being viewed by others

References

Lev-Yadun S, Ne’eman G (2007) Color changes in old aposematic thorns, spines, and prickles. Isr J Plant Sci 54(4):327–333

Ronel M, Lev-Yadun S (2009) Spiny plants in the archaeological record of Israel. J Arid Environ 73(8):754–761

Cooper SM, Ginnett TF (1998) Spines protect plants against browsing by small climbing mammals. Oecologia 113(2):219–221

Gowda JH (1996) Spines of Acacia tortilis: what do they defend and how? Oikos 77:279–284

Lucas PW, Turner IM, Dominy NJ, Yamashita N (2000) Mechanical defences to herbivory. Ann Bot-London 86(5):913–920

Halpern M, Raats D, Lev-Yadun S (2007) Plant biological warfare: thorns inject pathogenic bacteria into herbivores. Environ Microbiol 9(3):584–592

Mauseth JD (2006) Structure–function relationships in highly modified shoots of Cactaceae. Ann Bot-London 98(5):901–926

Bobich EG, Nobel PS (2001) Vegetative reproduction as related to biomechanics, morphology and anatomy of four cholla cactus species in the Sonoran desert. Ann Bot-London 87(4):485–493

Rundel PW, Ehleringer J, Mooney HA, Gulmon SL (1980) Patterns of drought response in leaf-succulent shrubs of the coastal Atacama Desert in Northern Chile. Oecologia 46(2):196–200

Mauseth JD (1977) Cytokinin-and gibberellic acid-induced effects on the determination and morphogenesis of leaf primordia in Opuntia polyacantha (Cactaceae). Am J Bot 64(3):337–346

Gibson LJ (2012) The hierarchical structure and mechanics of plant materials. J R Soc Interface 9(76):2749–2766

Malainine ME, Dufresne A, Dupeyre D, Mahrouz M, Vuong R, Vignon MR (2003) Structure and morphology of cladodes and spines of Opuntia ficus-indica. Cellulose extraction and characterisation. Carbohyd Polym 51(1):77–83

Mosco A (2009) Micro-morphology and anatomy of Turbinicarpus (Cactaceae) spines. Rev Mex Biodivers 80(1):119–128

Peharec P, PosiloviĆ H, Balen B, Krsnik-Rasol M (2010) Spine micromorphology of normal and hyperhydric Mammillaria gracilis Pfeiff. (Cactaceae) shoots. J Microsc-Oxford 239(1):78–86

Gindl-Altmutter W, Keckes J (2012) The structure and mechanical properties of spines from the cactus opuntia ficus-indica. Bioresources 7(1):1232–1237

Schlegel U (2009) The composite structure of cactus spines. Bradleya 27:129–138

Loza-Cornejo S, Terrazas T (2003) Epidermal and hypodermal characteristics in North American Cactoideae (Cactaceae). J Plant Res 116(1):27–35

Spurr AR (1969) A low-viscosity epoxy resin embedding medium for electron microscopy. J Ultrastruct Res 26(1–2):31–43

Meylan BA (1967) Measurement of microfibril angle in Pinus radiata by X-ray diffraction. Forest Prod J 17:51–58

Cave ID (1997) Theory of X-ray measurement of microfibril angle in wood. Wood Sci Technol 31(4):225–234

Stuart SA, Evans R (1995) X-ray diffraction estimation of the microfibril angle variation in eucalypt wood. Appita J 48(3):197–200

Wimmer R, Lucas BN, Oliver WC, Tsui TY (1997) Longitudinal hardness and Young’s modulus of spruce tracheid secondary walls using nanoindentation technique. Wood Sci Technol 31(2):131–141

Yu Y, Fei BH, Zhang B, Xiang Y (2007) Cell-wall mechanical properties of bamboo investigated by in-situ imaging nanoindentation. Wood Fiber Sci 39(4):527–535

Oliver WC, Pharr GM (2004) Measurement of hardness and elastic modulus by instrumented indentation: advances in understanding and refinements to methodology. J Mater Res 19(01):3–20

Oliver WC, Pharr GM (1992) Improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7(6):1564–1583

Sneddon IN (1965) The relation between load and penetration in the axisymmetric boussinesq problem for a punch of arbitrary profile. Int J Eng Sci 3(1):47–57

Zou L, Jin H, Lu W-Y, Li X (2009) Nanoscale structural and mechanical characterization of the cell wall of bamboo fibers. Mater Sci Eng C 29(4):1375–1379

Wang Y, Leppänen K, Andersson S, Serimaa R, Ren H, Fei B (2012) Studies on the nanostructure of the cell wall of bamboo using X-ray scattering. Wood Sci Technol 46(1–3):317–332

Wu Y, Wang SQ, Zhou DG, Cheng X, Zhang Y (2009) Use of nanoindentation and silviscan to determine the mechanical properties of 10 hardwood species. Wood Fiber Sci 41(1):64–73

Wu Y, Wang SQ, Zhou DQ, Cheng X, Zhang Y, Cai ZY (2010) Evaluation of elastic modulus and hardness of crop stalks cell walls by nano-indentation. Bioresour Technol 101(8):2867–2871

Konnerth J, Gierlinger N, Keckes J, Gindl W (2009) Actual versus apparent within cell wall variability of nanoindentation results from wood cell walls related to cellulose microfibril angle. J Mater Sci 44(16):4399–4406. doi:10.1007/s10853-009-3665-7

Tze WTY, Wang S, Rials TG, Pharr GM, Kelley SS (2007) Nanoindentation of wood cell walls: continuous stiffness and hardness measurements. Compos Part A Appl S 38(3):945–953

Gindl W, Schöberl T (2004) The significance of the elastic modulus of wood cell walls obtained from nanoindentation measurements. Compos Part A Appl S 35(11):1345–1349

Wang XQ, Ren HQ, Zhang B, Fei BH, Burgert I (2011) Cell wall structure and formation of maturing fibres of moso bamboo (Phyllostachys pubescens) increase buckling resistance. J R Soc Interface 9(70):988–996

Tan T, Rahbar N, Allameh SM, Kwofie S, Dissmore D, Ghavami K, Soboyejo WO (2011) Mechanical properties of functionally graded hierarchical bamboo structures. Acta Biomater 7(10):3796–3803

Yu Y, Tian GL, Wang HK, Fei BH, Wang G (2011) Mechanical characterization of single bamboo fibers with nanoindentation and microtensile technique. Holzforschung 65(1):113–119

Jäger A, Bader T, Hofstetter K, Eberhardsteiner J (2011) The relation between indentation modulus, microfibril angle, and elastic properties of wood cell walls. Compos Part A Appl S 42(6):677–685

Rao KMM, Rao KM (2007) Extraction and tensile properties of natural fibers: vakka, date and bamboo. Compos Struct 77(3):288–295

Li H, Shen S (2011) The mechanical properties of bamboo and vascular bundles. J Mater Res 26(21):2749–2756

Acknowledgements

This work is supported by NSF (30970557, 91023026) of China, and the central university basic scientific research business expenses special funds (2012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, F., Guo, W. Structural and mechanical properties of the spines from Echinocactus grusonii cactus. J Mater Sci 48, 5420–5428 (2013). https://doi.org/10.1007/s10853-013-7335-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7335-4